Packaging manufacturer Ardagh Group has invested €2.4 million in a new state-of-the-art warehousing facility at its Deventer production facility in the Netherlands.

The company says that the new warehouse features the latest in stock management solutions, as well as a fleet of fully automated forklift trucks, known as ‘Automated Guided Vehicles’ (AGVs).

These AGVs are controlled by advanced software, and are designed to take four pallets at a time from the production area to the warehouse for storage, and then take them back out again to one of the five loading bays for shipment.

The system has been designed to stack the pallets four high in deep bays, which is the first time such a stack configuration has been automated in Europe.

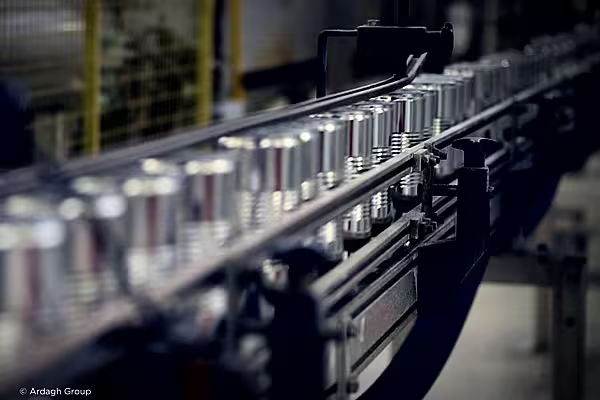

The new warehouse is attached to the DWI (Drawn, Walled and Ironed) metal production facility, which produces two-piece food cans.

Jan de Bruin, Plant Manager of the Deventer Production Facility commented, “Our new warehouse, adjacent to the production facility, gives us and our customers a more efficient, smoother, streamlined logistical service.”

"It is longer than a football pitch (or the equivalent size of 40 indoor tennis courts), is equipped with the latest software and hardware systems to monitor movements, and, we calculate, will remove 12 tonnes of CO2 through fewer truck movements to our previous external warehouses."

© 2016 European Supermarket Magazine – your source for the latest retail news. Article by Jenny Whelan. To subscribe to ESM: The European Supermarket Magazine, click here.