For almost a decade, WITRON Integrated Logistics and Canadian food retailer Sobeys have maintained a close partnership. Now, with two warehouse-automation projects jointly realised in Vaughan, Ontario, and Terrebonne, Quebec, the two companies are about to add another chapter to this success story.

In mid-May 2014, both companies signed a contract to extend the existing dry-grocery facility in Ontario by adding a fully automated case-picking system for fresh and frozen goods.

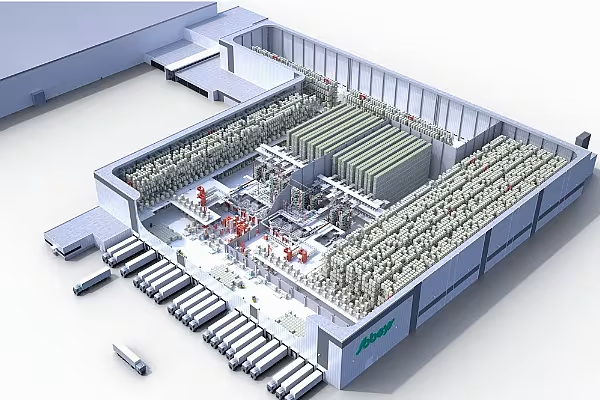

The new facility will have an area of approximately 245,000 square feet, and its fully automated case-picking system, called OPM (Order-Picking Machinery), has been designed to handle a daily peak picking performance of almost 170,000 cases. The article range covers about 3,800 different products.

An automated shipping buffer will optimise the entire dispatch process. The warehouse will supply 783 stores with frozen goods and 829 stores with perishable products. Productive use of the distribution centre is scheduled for autumn 2016.

WITRON will implement two of its systems into the new Sobeys distribution-centre extension: the Case-Picking System (CPS) and the aforementioned Order-Picking Machinery (OPM). Both systems are currently being operated in Sobeys' existing dry-grocery facilities.

The OPM system really is a fully automated case-picking solution, as almost all processes, apart from unloading and loading the trailers at shipping and receiving, are automated. Thus, the system virtually eliminates picking labour within the DC.

The benefits of such a system extend beyond the DC, with a reduction in effort to fill store shelves as a result of store-friendly pallets. In addition, transportation benefits can be realised from improved order-pallet density. All of these benefits are made possible through WITRON’s innovative and proprietary COM (Case-Order Machine) at the heart of the OPM system.

The COM allows cases to be automatically stacked atop order pallets in a store-friendly sequence, without any of the gaps around the cases that result in most robotic pallet-building applications. At the new Vaughan extension, WITRON will integrate ten COMs. Once system ramp-up is complete, Sobeys will have a total of 42 COMs in use at its existing sites.

Although revolutionary in its approach, the majority of the components and processes that drive the OPM are standard within the world of warehouse automation. The OPM is highly flexible to business needs. Projects range from handling 300 to 18,000 SKUs, with as few as three COMs to as many as 70 COMs, and handling volumes from 13,000 cases per day to 600,000 cases per day. So far, a cost-efficient solution has been found for every customer's task.

All in all, the benefits for Sobeys are high transparency, lowest error rates, and optimisation with regards to service and logistics costs.

The picking of large and bulky articles in both cooler and freezer at the Vaughan DC will take place in WITRON’s Car-Picking System (CPS). CPS is a pallet-picking solution with path-optimised order-picking supported by pick-by-voice operator guidance. The pickfront is automatically replenished by AS/RS cranes. The CPS module will be integrated into an automated high-bay warehouse within each chamber. The freezer pallet high-bay warehouse will have five pallet AS/RS cranes servicing approximately 14,200 storage locations, while the cooler high-bay warehouse will have two pallet AS/RS cranes servicing approximately 4,800 storage locations.

With annual sales of more than CAD 24 billion, 125,000 employees and 1,500 stores, Sobeys, Inc. is Canada’s second-largest food retailer.

Sobeys has been serving the food-shopping needs of Canadians for 108 years. A wholly owned subsidiary of Empire Company Ltd, Sobeys owns or franchises approximately 1,500 stores in all ten provinces under retail banners that include Sobeys, Safeway, IGA, Foodland, FreshCo, Thrifty Foods and Lawton’s Drug Stores, as well as more than 350 retail fuel locations. Sobeys and its franchisees and affiliates employ more than 125,000 people.

As a general contractor, WITRON is responsible for the entire design and realisation of IT, control engineering and mechanical components. All conveyor-system elements will be designed and produced by WITRON's subsidiary, FAS. The system will work 20 hours a day, seven days a week.

© 2016 European Supermarket Magazine – your source for the latest retail news. To subscribe to ESM: The European Supermarket Magazine, click here.