There are no merchandisers in the typical gas station outlet – here the operator both arranges goods, sells gasoline, and cooks hot dogs on his or her own. What is the best way to monitor the shelf display, if there are several hundred such shops, and they are located in different parts of the country?

We need a tool to analyse the activities of operators of gas stations and retail outlets, which will enable the operators themselves to automate the comparison of layout against planograms.

Mike Savitsky, Tech Lead of Goods Checker IT Solution at IBA Group, will share the outputs of a pilot project the group undertook with a gas station chain, thanks to which operators were able to compare layouts against planograms faster and more efficiently, while also tracking out of stocks, and managers were able to supervise all business processes.

Gas Station Chains – Large, Extensive And Complicated

Back in 2020, the number of gas-filling stations in Europe crossed the threshold of 100,000. A third of them are located in Italy and Germany. Most of all, gas stations are owned by 8,000 retailers – there is huge competition in the fuel market in Europe.

Usually, gas stations of one chain are scattered throughout the country. Many of them are located in remote areas – on highways, in small towns and near the border.

Gas station operators who run shops at their gas stations must provide service to customers while arranging goods and monitoring the in-store display. Compliance with arrangements for laying out with suppliers is essential.

At the same time, each station has different space planning, so the equipment for placing goods is also different. It is impossible to come up with one all-purpose workflow here.

How Gas Station Operators Manage Layout

Customers. In the morning, an average of five to ten customers comes to the soft drinks rack in one hour. At rush hour, there can be several times more of them — people take goods, move them, and sometimes put them in the wrong places. Gas station operators rarely approach the shelves at this time, because they sell fuel, serve out coffee cups, and cook hot dogs. They have no time to constantly handle goods.

Planograms. Planograms are generated automatically, based on the conditions of placement, the size of goods and racks. Usually a planogram is an Excel document without pictures, which is difficult to process manually. Planograms rarely change radically, but almost every week a few items change. Therefore, the gas station operator has to check the entire planogram every time.

Equipment. A system that produces planograms sometimes takes rack dimensions from the outer edge (including the width of the side walls). In such cases, the planogram may show one product more than actually fits the shelf. Cans and bottles that tend to fall off the shelf are the result of laying out according to such a planogram.

Design. Sometimes the packaging design changes. One of the largest producers of soft drinks makes a New Year-special label. But the documents do not specify the design of delivered product and the way to display it.

Therefore, the challenge is to come up with a solution for effective display checking, including out-of-stock monitoring. Doing it manually is difficult, time consuming and expensive.

What Changes Computer Vision Introduces In The Activities Of Gas Station Operators

Technology. Gas station operators were offered to use the Goods Checker cloud service.

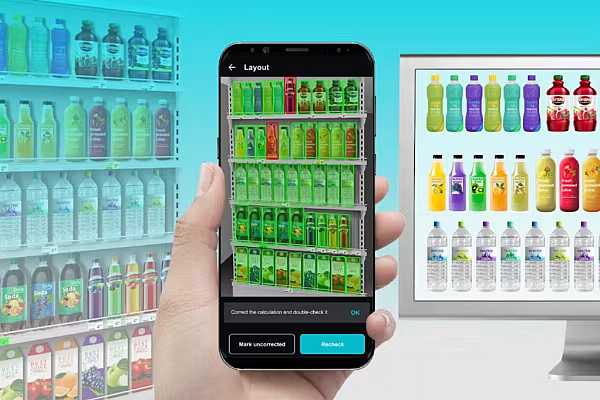

Goods Checker is a SaaS solution for manufacturers and distributors of FMCG products that automates all merchandising stages. The solution consists of several modules. Using the Check & Go mobile app, the user just needs to take a picture of a shelf with goods. Using regular mobile data or Wi-Fi connectivity available at the gas station, this information is then transmitted to the data centre. There, the Shelf Eye module processes the incoming images using computer vision and immediately shows the user in the application what is wrong with the layout. It takes no more than 30 seconds to process one photo.

Customers. The use of computer vision by a gas station operator eliminates the need to manually compare the planogram with the realogram. The mobile app does this based on photos. The gas station operator identifies and corrects wrong displays five to ten times faster. The manager automatically receives a report and can analyse the performance of outlets.

Planograms. When changing the planogram, you can just take a photo of the shelf – the goods that need to be rearranged will be highlighted in red. If the distance between the shelves is very small, you can take several photos – Goods Checker will align them and merge into one.

Equipment. Goods Checker will prompt any flaws in the generation of planograms for different types of equipment. The Plano Creator module will help you see the dimensions of the racks and the number of goods that can actually fit in them. Based on the QR code scanned by the gas station operator, the application identifies the type of rack and the planogram provided for it.

Design. The application allows entering new design for products that are already on display. Then, the application will correctly recognise them and take them into account in the display analysis.

How Gas Station Chain Operators Used Computer Vision In Their Operations

IBA Group carried out a pilot project for a major gas station chain. Its experts:

- Trained gas station operators to work in the application, and they helped collect data for the project

- Prepared complete taxonometry of all 200 soft drinks by type

- Trained the neural network to identify products and not confuse them with advertising images of the same products on the trading floor, as well as classify images in accordance with taxonometry

- Created a tool for identifying equipment by QR code

Goods Checker makes it easier for gas station operators to update existing shelf layouts in accordance with the new planogram.

The category manager is able to check the leftover stock. This solution provides monitoring of out-of-stock items in a timely manner. Information from the mobile app is displayed on the Goods Checker dashboard and helps to schedule deliveries in order to quickly deliver the required goods without changing processes.

Thanks to process automation, company leaders not only supervise the operators of gas stations, but are also able to firmly acknowledge to suppliers their obligations to fill certain shares of shelves.

Pilot Project Results – If A Human Is Busy, Let The Computer Work

The main task of the gas station operator is to serve customers, that is, to have a client-facing role. He should not wander among the shelves and rearrange goods on them while a line of customers is gathering at the checkout. The gas station is not a shopping centre; here, people don't have time for idle waiting.

The routine job of checking the shelf layout and stock monitoring can and should be entrusted to a computer. In the pilot project, these tasks were performed by the Goods Checker service, a SaaS solution from IBA Group for automating merchandising using artificial intelligence.

As a result, the mobile app has helped gas station operators compare planograms with realograms faster and more efficiently through updating or correcting the goods display on the shelves. Category managers identified out-of-stock in time, and executives supervised all business processes.

© 2023 European Supermarket Magazine – your source for the latest technology news. Sponsored content. Click subscribe to sign up to ESM: European Supermarket Magazine.