Energy Recovery recently helped reduce costs and improve performance for a retailer in Northern Italy, with its PX G1300 solution.

Addressing climate change is a global imperative, and transitioning from hydrofluorocarbons (HFCs) to low-global warming potential (low-GWP) natural refrigerants in commercial refrigeration is an effective way to reduce emissions.

A supermarket in Northern Italy, where regulation limits HFC use, recently made a significant push towards sustainability with the installation of a carbon dioxide (CO2)-based system, helping to reduce its emissions, as well as improve efficiency.

While it is a leading natural refrigerant, and therefore kinder to the environment, CO2-based systems can be energy intensive, increasing operating costs.

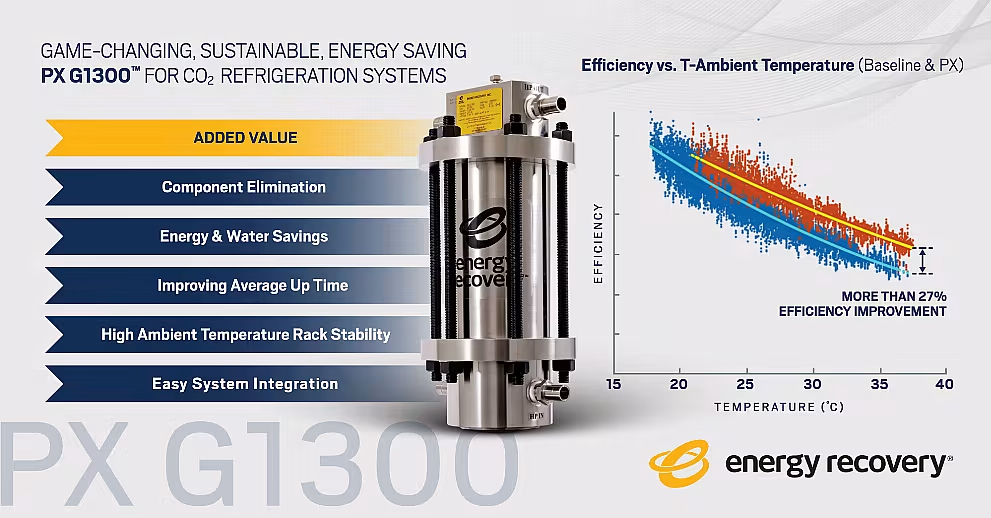

Introducing The PX G1300

In collaboration with Epta, a prominent player in commercial refrigeration, this supermarket incorporated the PX G1300 device from Energy Recovery into its CO2 system.

The device was integrated into Epta’s new XTE (Extra Transcritical Efficiency) system, the company’s next-generation CO2 refrigeration technology.

The PX G1300 device was chosen for its ability to recycle pressure energy, making the system more efficient. This, in turn, enables performance improvements at temperatures between 20°C to 40°C, increasing annual efficiency as it allows the system to operate for longer periods.

Epta also selected the PX G1300 due to its simple design, low maintenance requirements, and potential for improving rack stability at high temperatures, a challenge for this particular location.

Effective Results

Following the installation of the PX G1300 device, the supermarket saw impressive efficiency improvements – at temperatures between 35-40°C, energy efficiency increased by more than 25%. Also, above 40°C, the improvement was over 30% when compared to a standard CO2 booster system.

This is notable as CO2 refrigeration systems typically lose efficiency as temperatures rise. The PX G1300 technology overcame this issue by providing free compression power, thereby enhancing efficiency levels.

The integration of the PX G1300 also ensures high-temperature rack stability, vital for regions prone to extreme weather conditions, including heat waves.

The additional capacity it provides ensured consistent operation beyond the system’s original design parameters, making the supermarket well-prepared for future energy variations and minimising the risk of refrigeration failure and associated revenue losses.

To learn more, visit energyrecovery.com.